MASTERMIX CONCRETE RESURFACING AND REPAIR

Are you looking for a solution for your damaged masonry and cementitious based substrates? At Mastermix, we stock a range of concrete coatings for resurfacing and repair products which have been scientifically formulated to future proof your masonry and cementitious based substrates from marine and high acidity environments. In fact, we believe that our product ranges will perform better than the original solution.

The Difference Between Concrete Resurfacing and Repair - concrete coatings

Concrete is a tried and tested solution which has stood the test of time. Having said that, concrete can structurally fail due to a variety of factors including: Insufficient reinforcement, Marine environments, Acid damage, Chemical damage, Weather exposure, Impact damage, Excessive loads, Structural damage, Fire damage and Seismic damage. While there are many risk factors which can cause significant damage you probably won’t need to remove the existing cement and start again as most of these problems can be fixed either with specialist resurfacing and repair products. Not only will this save you time and money, with Mastermix concrete coatings the end result could end up having a longer lifespan than the original concrete.

TYPES OF DAMAGE

Here are some of the most typical types of damage you may be experiencing

We would love to help you with your next project so get in touch with Mastermix before deciding on the right concrete coating or concrete repair product. We can help you save time and money by working with you to understand your requirements first. Get the job done right the first time and it will last a long time. Understanding the type of damage and what caused the damage in the first place is an important step towards finding a solution.

Depending on the extent of the damage and how the damage came about, concrete coatings resurfacing and repair are two processes which could be used to fix the problem. As mentioned most concrete resurfacing and repair products are designed to perform in specific environments so selecting the right solution is parment to future proofing your project.

Probably the most common problem with concrete surfaces is cracks forming. This can happen very quickly, especially if insufficient control joints have not been incorporated however larger stress fractures or structural cracks can also form over time. As not all cracks are created equal it is important to be able to understand when you should consider fixing them. Generally speaking we recommend fixing the problem if:

- The cracks are compromising the structural integrity of the substrate.

- If water is pentrentating the structure particularly when water is undermining the foundation

- The cracks are affecting the aesthetics of the structure to a sufficient degree that you are not happy with the overall look

Which is otherwise known as pitting is when little pockmarks begin to pepper the surface of the concrete. This is caused by freeze-thaw cycles causing moisture to expand during the thawing process and putting pressure on the top layers of concrete.

When the soil beneath a concrete slab experiences significant drying and thus shrinkish or wasn’t sufficiently compacted at the time of pouring. The resulting changes to the foundation can cause a general collapse of the affected area into the newly formed recess.

Just as changes to the foundation can cause settlement issues it can also cause a concrete slab to lift. Probably the most common occurrence is when a tree root lifts up a pad.

One of the most common problems our clients call us for help with is the extreme environments their concrete structures call home. Water and wastewater treatment plants, manholes, water tanks in marine environments and other acidic environments take a huge toll on the structural integrity of a structure.

prepared, repaired, and overlaid

Concrete Resurfacing

Concrete resurfacing is the process in which concrete is prepared, repaired, and overlaid with a thin cement based surface. It is applied over the existing masonry or concrete based substrate and incorporates a polymer blend which ensures there is good adhesion between the concrete resurfacing product and the original concrete surface.

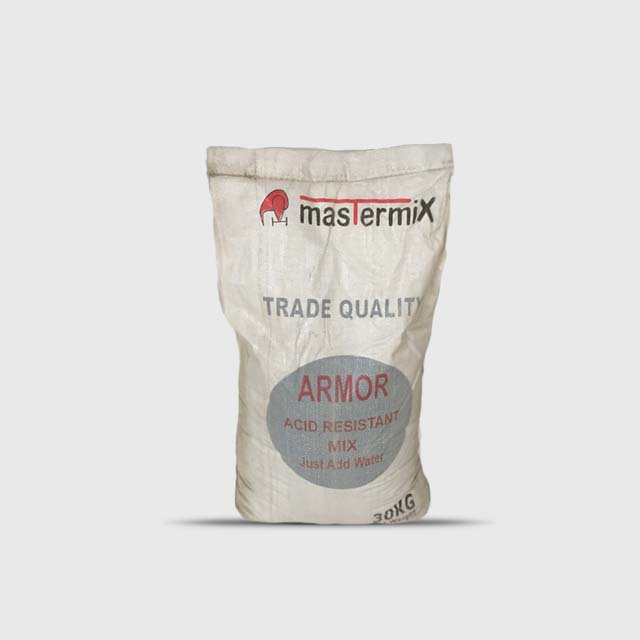

At Mastermix, we take resurfacing to the next level by offering a number of products in this category which are designed to excel under different conditions:

Our hydrophobic and heavy duty barrier that is waterproof and acid resistant. Click here to see product

Our durable resurfacing solution that leverages the properties of recycled glass to form an acid free and inert top coat. Click here to see product

Our waterproof coating system is designed to be applied internally and externally to almost any stable substrate including concrete, block work and steel. Click here to see product

Concrete Resurfacing

To better understand the concrete resurfacing process, here are the steps involved. As extensive as this may sound, it is still quicker and more economical than pouring concrete for a whole new surface.

- Preparation – The existing substrate must be cleaned with a power washer to remove dirt, grease, loose materials and foreign matter.

- Colouring Tint – As the resurfacing product will cover the original surface a colour tint may be added to the mix to match the original look or create something new.

- Application – Once the surface has been prepared the resurfacing product is ready to be applied by roller, brush or sprayed. Depending on the solution thickness and finishing requirements may vary.

- Curing – Depending on temperature, humidity and the dampness of the original surface the newly applied layer will take about 30 minutes to become tacky and cure in 4 hours. Wait at least that time before applying any additional coats.

Concrete Resurfacing Guide

While concrete resurfacing deals with the top 3mm, concrete repair is about ensuring the structural soundness of your substrate. It is fairly common to first repair a structure before applying a concrete resurfacing product for a professional finish that is consistent with the look required. Planning is essential as understanding what caused the damage in the first place is the first step towards putting a long term solution in place.

Depending on factors such as the weather all year round, environmental conditions such as acidity, load management, moisture and proximity to the ocean combined with strategic decisions like site access and will the site be closed down during the repair process.

Finding a product which can satisfy these conditions can be a real challenge. At Mastermix, we are used to working in difficult environments and working on projects which are still operational while we make the repairs. We worked with the Timaru District Council to fix an operational treatment plant where the work had to be split into two stages to ensure the plant could remain functional.

Our repair range covers a wide variety of conditions which we can help you understand how to apply to your project.

Mastermix HSR – Our high stress point solution which offers fast curing times and high compression strength characteristics. Click here to see product

Mastermix Rapid Repair – Our hydrophobic repair system which offers fast curing times and critical early high compression strength for load bearing repair work.

For more information on the type of projects, testimonials and product breakdowns for the entire range.

Selecting the right premix concrete product to suit your project’s specific requirements can be difficult which is why MasterMix is here to save you time and money by walking you through the selection process.